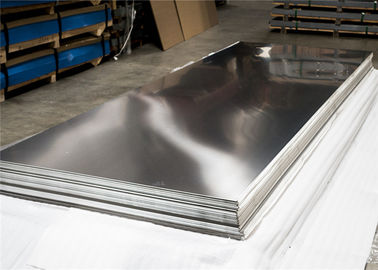

Duplex Stainless Steel 310S Sheet AISI 321 304 310S stainless steel sheet plate 2B

Description:

Alloy 310 is an austenitic stainless steel that combines excellent high temperature properties with good ductility and weldability. It is typically used for elevated temperature applications as its high chromium and nickel content provide solid corrosion resistance, excellent resistance to oxidation, and superior strength. Due to its high chromium and nickel content, it is superior to 304 or 309 stainless in most environments.

Haosteel stainless 310 sheet and processed flat bar provides superior resistance to corrosion and heat exposure, in even the most demanding environments.

| Product name |

Stainless steel plate sheet |

| Brand name |

HAOSTEEL |

| Standard |

ASTM A240, ASTM A480, EN10088, JIS G4305 |

| Material |

304, 316L, 321, 310S, 1.4301, 1.4307, 1.4404, S31803, S32750, 904L, Monel 400, Inconel 800 |

| Surface |

NO.1,2B,NO.4,BA,SB,Satin,Brushed,Hairline,Mirror |

| Certificate |

ISO9001, CE, SGS, TUV, DNV, BV, LR, GL, NK, RMRS |

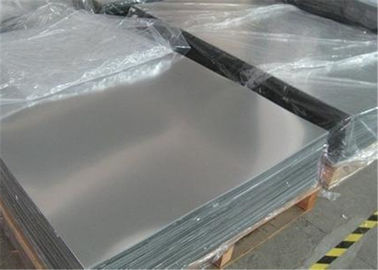

| Packing |

In wooden cases,in wooden pallets |

| Chemical Composition(%) |

| Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Cu |

| 201 |

≤0.15 |

≤0.75 |

5.5~7.5 |

≤0.060 |

≤0.03 |

16.00~18.00 |

3.5~5.5 |

- |

0.08 |

1.5 |

| 202 |

≤0.15 |

≤1.00 |

7.5~10.00 |

≤0.060 |

≤0.03 |

17.00~19.00 |

4.0~6.0 |

- |

|

|

| 301 |

≤0.15 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

6.00~8.00 |

- |

|

|

| 302 |

≤0.15 |

≤1.00 |

≤2.00 |

≤0.035 |

≤0.03 |

17.00~19.00 |

8.00~10.00 |

- |

|

|

| 304 |

≤0.07 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

18.00~20.00 |

8.00~10.50 |

- |

|

|

| 304L |

≤0.030 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

18.00~20.00 |

9.00~13.00 |

- |

|

|

| 310S |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

24.00~26.00 |

19.00~22.00 |

- |

|

|

| 316 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

10.00~14.00 |

2.00~3.00 |

|

|

| 316L |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

16.00~18.00 |

12.00~15.00 |

2.00~3.00 |

|

|

| 321 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.03 |

17.00~19.00 |

9.00~13.00 |

- |

|

|

| 430 |

≤0.12 |

≤0.75 |

≤1.00 |

≤0.040 |

≤0.03 |

16.00~18.00 |

|

- |

|

|

| 2205 |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.030 |

≤0.015 |

22.00~23.00 |

4.5~6.5 |

2.5~3.5 |

|

|

| 2507 |

≤0.03 |

≤0.08 |

≤1.20 |

≤0.035 |

≤0.015 |

24.00~26.00 |

6.00~8.00 |

3.0~5.0 |

|

|

| 904L |

≤0.02 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.035 |

19.00~23.00 |

23.00~28.00 |

4.0~5.0 |

1.0~2.0 |

|

|

INCONEL

028

|

≤0.03 |

≤1.00 |

≤2.50 |

≤0.030 |

≤0.030 |

≤28.0 |

≤34.0 |

≤4.0 |

≤1.4 |

|

|

MONEL

400

|

≤0.30 |

≤0.5 |

≤2.00 |

- |

≤0.024 |

- |

≥63.0 |

- |

≤34.0 |

|

|

INCONEL

800

|

≤0.10 |

≤1.00 |

≤1.50 |

- |

≤0.015 |

≤23.0 |

≤35 |

4.0~5.0 |

≤0.75 |

Ti≤0.6

Al≤0.6

|

Mechanical properties:

| Grade |

Tensile Strength

MPa(min.) |

Yield Strength 0.2%

Offset MPa (min.) |

Elongation

% in50 mm (min.) |

Hardness

(HB) max |

Hardness

(HRB) max. |

| 310/310S |

515 |

205 |

40 |

217 |

95 |

Corrosion resistance:

Provides excellent corrosion resistance

High chromium content allows for good aqueous corrosion resistance

Excellent resistance at normal temperatures and also has good resistance to oxidizing and carburizing atmospheres

Heat resistance:

Good resistance to oxidation in intermittent service in air at temperatures up to 1040°C and 1150°C in continuous service.

Good resistance to thermal fatigue and cyclic heating.

Widely used where sulphur dioxide gas is encountered at elevated temperatures.

Continuous use in 425-860°C range not recommended due to carbide precipitation, if subsequent aqueous corrosion resistance is needed

Generally used at temperatures starting from about 800 or 900°C – above the temperatures at which 304H and 321 are effective.

Fabrication:

Commonly used in the heat treatment and process industries due to high temperature and corrosive environments

Often fabricated into complex structures

Roller-forms, stamps and draws readily

Because 310 work hardens, severe forming operations should be followed by an anneal

Weldability:

Austenitic stainless steel is generally considered to be weldable

Generally considered to have weldability equivalent to 304 and 304L

Applications:

The higher alloyed stainless steels generally have excellent strength at elevated temperatures along with outstanding resistance to creep deformation and environmental attack. Therefore, Alloy 310 is used widely in industries such as heat treatment and chemical processing. Some examples include:

Furnace Parts

Oil Burner Parts

Heat Exchangers

Welding Filler Wire and Electrodes

Annealing Covers

Combustion Tubes

Fire Box Sheets

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!