Dry burning electric heating pipe product features

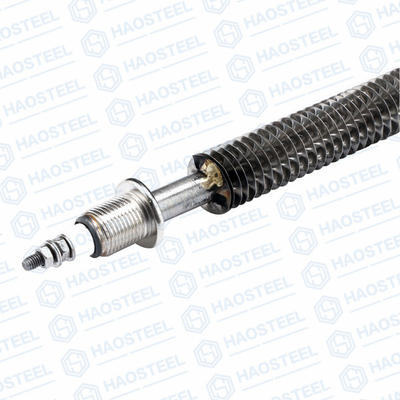

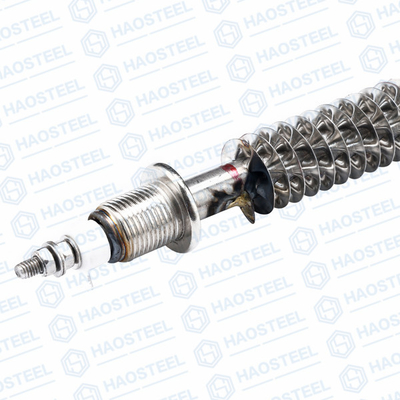

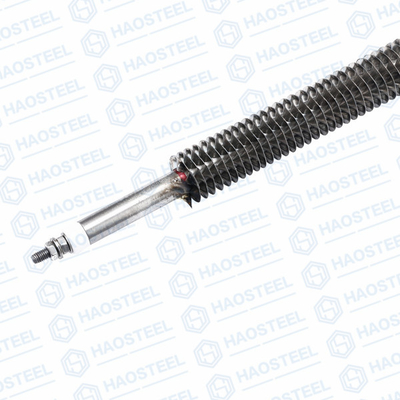

The heating tube is a metal tube as the shell, along the center of the tube axial distribution of spiral electrothermal alloy wire (nickel chromium, iron chromium alloy), the gap filled with compaction of magnesia with good insulation and thermal conductivity, both ends of the tube with silica gel or ceramic seal.

Stainless steel electric heating tube is a special electric component that converts electric energy into heat energy. Because of its cheap price, convenient use, convenient installation, no pollution, it is widely used in various heating occasions. The service life of stainless steel dry heating tube is very long, and the service life of the general design is more than 5000 hours.

1. Voltage can be designed as: 12-660V

2. Single injection power: 50W-20KW

3. Material: 10# iron, T4 copper, stainless steel, Ti titanium, etc.

4. Specifications: U type, W type, special-shaped, with heat dissipation fin electric heating tube, explosion-proof electric heating tube

Requirements for materials of dry-fired electric heating tubes

1. The quality of the material is very important in the factors affecting the quality of the stainless steel dry burning electric heating tube. The reason. Reasonable selection of raw materials for dry burning electric heating tube is the premise to ensure the quality of dry burning electric heating tube.

3. Pipe selection principle: temperature resistance, corrosion resistance.

4 resistance wire selection: Cr20Ni80

5. Selection of magnesium oxide powder: industrial grade magnesium oxide powder

6 sealing material selection: silicone oil +704 sealant

Dry - fired electric heating tube advantage

1. Small volume and large power: the electric heater mainly uses cluster tubular heating elements inside, each cluster tubular heating element has a maximum power of 5000KW.

2. Fast thermal response, high temperature control precision, high comprehensive thermal efficiency.

3. Wide range of application and strong adaptability: the circulating heater can be applied to explosion-proof or ordinary occasions, its explosion-proof grade can reach B and C, and its pressure resistance can reach 10Mpa. And can be used according to user needs of the vertical or horizontal cylinder installation.

4. High heating temperature: the maximum working temperature of the heater can reach 850℃, which can not be obtained by the general heat exchanger.

5. Full automatic control: through the design of the heater circuit, it is convenient to realize automatic control of temperature, pressure, flow and other parameters at the outlet, and can be networked with the computer to realize man-machine dialogue.

6. Long life and high reliability: the heater is made of special electric heating materials, and the design power load is reasonable, the heater adopts multiple protection, which greatly increases the safety and life of the heater.

7. Dry stainless steel electric heating pipe based on metal shell, along the axial uniform spiral tube center electric thermal bonding wire, nickel chromium, iron chromium alloy) the gap filling compaction with good thermal conductivity of insulating oxide magnesia, using silica gel or ceramic seal on both ends of the tube, the metal armoured electric heating element to heat the air, metal molds and all kinds of liquid. ] Evenly distributed in the high temperature resistant stainless steel seamless tube of high temperature resistance wire, dense part in gap to fill in the performance of thermal conductivity and good insulation performance are the crystallization of magnesium oxide powder, this kind of structure not only advanced, high thermal efficiency, and even heating, when high temperature resistance wire in an electric current passes through the heat to the metal surface diffusion through crystallization of magnesium oxide powder, Then transfer to the heated parts or air to achieve the purpose of heating.

Dry-fired electric heating tube classification

Dry electric heating tube, dry electric heating tube, stainless steel dry electric heating tube, radiator dry electric heating tube, heat the water dry electric heating tube, dry heat pipes, mold dry electric heating tube, high temperature change color hose, hot runner electric heating circle, cigarette equipment dry electric heating tube, pharmaceutical machinery hair heat pipe, electroplating equipment, titanium heating tube, iron Christopher long heater dry electric heating tube, Titanium lead-free tin furnace dry burning electric heating tube, heating ring, plastic machinery electric heating ring, etc.

Dry fired electric heating tube heating tube electric heating tube application

Electric oven, chemical equipment, plastic molding and auxiliary equipment, hot press molding machinery, pharmaceutical machinery, sauna equipment, electric hot water boiler, kitchen equipment, industrial cleaning equipment, commercial air conditioning and water equipment, solar energy equipment, electric fryer, wave soldering electronic automation equipment, semiconductor eutectic welding heat input, die casting and not sprue injection, plastic, food, medical Thermal machinery components for treatment, textile, petroleum, machinery, electroplating, packaging and other industries.

Application range of dry burning electric heating pipe

Electric heating pipe, can be installed in the blowing pipe or other static, flowing air heating occasions; In hardware stamping, machinery manufacturing, automobile, textile, food, household appliances and other industries, especially in the air conditioner air curtain industry, stamping industry dry burning electric heating tube as hot air components are widely used, the common shape structure is: I (straight tubular), U, W (M), O (ring) and so on.

(dry heating electric heating tube heating tube electric heating tube, stainless steel electric heating tube products can be customized to customer requirements, to provide drawings, voltage, power, size)

1, die heating in modern industrial applications has been widely accepted by customers.

2, in the plastic mechanical heating system.

3. Pharmaceutical production line.

4. Heat treatment test in laboratory.

5. Chemical industry, etc.

Dry burning electric heating tube benefits:

1, small diameter, can do 3-25mm.

2, the length is not limited, can do 20-2000mm.

3, high power, is 2-5 times the power of the normal dry burning electric heating tube, can do (surface area of 20 watts/square centimeter), even foreign can do (surface area of 60 watts/square centimeter).

4, with simple structure, high mechanical strength, high thermal efficiency, safe and reliable, simple installation, long service life, no pollution, cheap and other characteristics, at the same time save electricity, safe use, can be bent into a variety of shapes, light, convenient disassembly and assembly.

Dry burning electric heating tube structure:

The typical structure of dry burning electric heating tube (the most popular structure) is the same as that of dry burning electric heating tube. It is generally composed of five parts: insulator, sealing material, lead rod, filling material, electric heating wire, metal casing and wiring end. The spiral electric heating wire and lead out help are located in the central metal casing, its manufacturing process is to spiral electric heating wire into seamless steel tube, copper tube or aluminum tube, the gap through the multi-tube filling machine evenly filled both insulation and heat conduction of oxidation medium, such as crystalline magnesium oxide powder (also available alumina or clean quartz sand). Then use the tube shrinking machine to shrink the tube diameter, so that the oxide medium is dense (density of 3.3g/cm3 or more), to ensure that the heating wire is isolated from the air, the central position does not offset and touch the tube wall. Like this. Unit area calorific value can increase ten times. Service life can also be correspondingly increased to more than 10 years. Compared with the heating element with the same amount of heat, the tubular dry-fired heating tube can save 5% of the heating material, and the thermal efficiency can reach more than 90%.

Dry burning electric heating tube difference:

1, appearance: dry electric heating tube is one end (one end), ordinary dry electric heating tube is two ends of the line.

2, internal structure: the winding way of dry burning heating tube and ordinary dry burning heating tube is different, especially now the imitation of imported U-type electric head tube, and ordinary dry burning heating tube has a great difference.

3, production process: dry burning electric heating tube in the production process than ordinary dry burning electric heating tube has more technology, such as shrinkable tube, which ensures that the power of dry burning electric heating tube is higher than ordinary dry burning electric heating tube, and the service time is long

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!