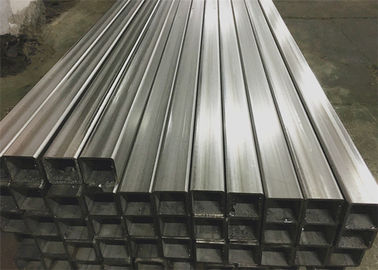

304 316 316L inox square/rectangular tubes stainless steel welded pipe

HAOSTEEL is one of the most professional manufacturer and supplier of stainless steel Tube.Stainless steel tube can be divided into seamless tube and welded tube according to production mode. Seamless tube can be divided into hot rolled tube, cold rolled tube, cold drawn pipe and extruded tube.The welded pipe is divided into straight welded pipe and spiral welded tube.

A stainless steel square tube is a hollow strip of steel called a square tube because the section is square.A large number of pipelines used to transport fluid, such as oil, natural gas, water, gas, steam, etc., in addition, bending and torsional strength at the same time, the weight is relatively light, so it is also widely used in the manufacturing of mechanical parts and engineering structures.

Classification of stainless steel square pipe: square pipe is divided into two categories: seamless pipe and welded pipe.By section shape can be divided into square and rectangular tube, widely used is circular steel tube, but there are some semicircular, hexagon, equilateral triangle, octagon and other special-shaped steel tube.

For the stainless steel square pipe under fluid pressure, hydraulic test shall be carried out to check its pressure resistance and quality, and no leakage, wetting or expansion shall be qualified under the specified pressure. Some steel pipes shall also be tested for flanging, flaring and flattening according to the standards or requirements.

Description:

316L stainless steel features

1) cold rolled products have good gloss and beautiful appearance;

2) excellent corrosion resistance, especially pitting corrosion resistance, due to the addition of Mo;

3) excellent high-temperature strength

4) excellent working hardenability (weak magnetism after processing)

5) no magnetism in the solid solution state;

Mechanical properties of 316L stainless steel:

Tensile strength (Mpa) 485 MIN yield strength (Mpa) 170 MIN elongation (%) 30 MIN area reduction (%) 40 MIN 316L stainless steel density 7.98g/cm3, hardness HRB<90 HV<200 HBS<187

The corrosion resistance of 316 l stainless steel is better than that of 304 stainless steel, in the process of pulp and paper production has good corrosion resistance performance, often used in pulp and papermaking equipment heat exchanger, dyeing equipment, film processing equipment, pipelines, has good resistance to chloride erosion performance, used in Marine environment, coastal areas with outside the building materials, water equipment, chemical, dyestuff, papermaking, oxalic acid and fertilizer production equipment;Photo, food industry, coastal facilities, ropes, CD rods, bolts, nuts.As well as advanced watch chain, case and so on.

Specification:

| The stainless steel square pipe |

| Standard |

ASTM,DIN 17458-85,DIN17456-85,JIS G 3463,JIS G 3448,GB13296-91,GB9948-88, |

| Material |

201,202,301,304,304L,310,310S,316,316L,317,317L,321,406,409,410,410S,904L,0Cr13,1Cr13,

2Cr13,3Cr13,4Cr13

|

| Specification |

Wall thickness |

1mm-80mm |

| Round thickness |

8mm-760mm |

| Square thickness1mm-20mm |

OD10*10mm-150*150mm |

| Rectangle 1mm-20mm |

10*20mm-100*200mm |

| Surface treatment |

NO.1,2B,NO.4,NO,8,HL |

| Production treatment |

Seamless steel pipe/ Welded steel pipe |

| Stainless steel pipe can be non –standard ordered |

Chemical Composition about stainless steel Tube:

| Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

| 201 |

≤0.15 |

≤0.75 |

5.5-7.5 |

≤0.06 |

≤0.03 |

3.5-5.5 |

16.0-18.0 |

- |

| 202 |

≤0.15 |

≤1.0 |

7.5-10.0 |

≤0.06 |

≤0.03 |

4.-6.0 |

17.0-19.0 |

- |

| 301 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

6.0-8.0 |

16.0-18.0 |

- |

| 302 |

≤0.15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

8.0-10.0 |

17.0-19.0 |

- |

| 304 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

8.0-10.5 |

18.0-20.0 |

- |

| 304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

9.0-13.0 |

18.0-20.0 |

- |

| 309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

12.0-15.0 |

22.0-24.0 |

- |

| 310S |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.035 |

≤0.03 |

19.0-22.0 |

24.0-26.0 |

- |

| 316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

| 316L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.045 |

≤0.03 |

12.0-15.0 |

16.0-18.0 |

2.0-3.0 |

| 321 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤0.03 |

9.0-13.0 |

17.0-19.0 |

- |

| 630 |

≤0.07 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

3.0-5.0 |

15.5-17.5 |

- |

| 631 |

≤0.09 |

≤1.0 |

≤1.0 |

≤0.030 |

≤0.035 |

6.50-7.75 |

16.0-18.0 |

- |

| 904L |

≤2.0 |

≤0.045 |

≤1.0 |

≤0.035 |

- |

23.0-28.0 |

19.0-23.0 |

4.0-5.0 |

| 2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.030 |

≤0.02 |

4.5-6.5 |

22.0-23.0 |

3.0-3.5 |

| 2507 |

≤0.03 |

≤0.80 |

≤1.2 |

≤0.035 |

≤0.02 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

| 2520 |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.045 |

≤0.03 |

0.19-0.22 |

0.24-0.26 |

- |

| 410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤0.03 |

- |

11.5-13.5 |

- |

| 430 |

≤0.12 |

≤0.75 |

≤1.0 |

≤0.040 |

≤0.03 |

≤0.60 |

16.0-18.0 |

- |

Product show

Stainless steels of various kinds are used in thousands of applications:

1. Domestic - cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2. Transport a exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

3. Oil and Gas - platform accommodation, cable trays, subsea pipelines.

4. Medical Surgical instruments, surgical implants, MRI scanners.

5. Food and Drink - Catering equipment, brewing, disilling, food processing

6. Water - Water and sewage treatment, water tubing, hot water tanks.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!